Printing is a part of wet processing technology which is carried out after pre-treatment of fabric or after dyeing of fabric for producing attractive designs on fabric or other materials. Printing is described as localizing dyes or pigments which are applied locally or discontinuously to produce various attractive designs on fabric. Main objectives of printing are producing attractive designs with well defined boundaries made by the artistic arrangement of a motif or motifs in one or more colors. If dyes and pigments are applied properly on fiber, printed fabrics are protected from friction and washing. A strong bonding is formed between dyes and fiber.

Steps of textile printing:

Eerstens, pre-treat fabrics before printing.

Use printing ingredient to prepare printing pasts. Printing performance depends on a well printing paste.

Use any printing methods to make an impression of the print pasts on the fabric, which is required.

Carry out steaming on printed fabric to fix the printing paste on the fabric.

After-treatment process neutralizes printed fabric.

Styles of printing: There are three different styles of printing: direct style of printing, discharge style of printing (including white discharge and color discharge) and resist style of printing (white resist and color resist)

Methods of printing: Using different instrument carry out printing. Use different method to produce impression on fabric. Demands of users vary methods which rely on the type of materials and the purpose of end product usage.

The followings are the methods applied for textile printing operation.

Block Printing

Burn-out Printing

Blotch Printing

Digitale druk

Duplex Printing

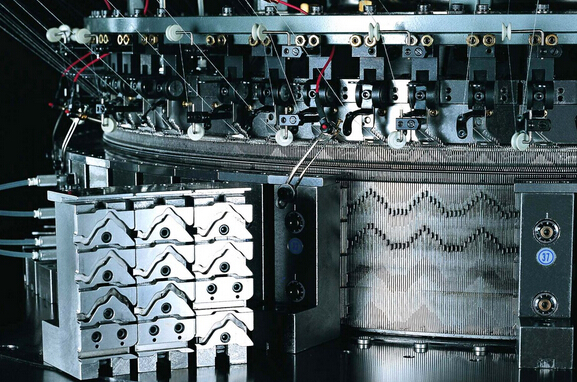

Engraved Roller Printing

Electrostatic Printing

Flock Printing

Ink-jet Printing

Jet Spray Printing

Photo Printing

Rotary Screen Printing

Screen Printing (Flat Screen)

Stencil Printing

Spray Printing

Transfer Printing

Warp Printing

Special Methods (Tie dyeing and Batik Printing)

In the early of history, printing was carried out by hand. Deesdae, different modern techniques are widely used for printing, which are controlled by computer. Graphics design is also widely used. Textile machines improve printing methods a lot.