2014, the German Engineering Federation (VDMA) ushered in the 10th anniversary of entering the Chinese market. June 26, Dr. ReinholdFestge VDMA chairman, said at a news conference: “Germany’s machinery manufacturing industry exports to China after years of growth, a downward trend in the past two years, in 2013, the German machinery and equipment industry in the Greater China. exports to the region reached 141 billion yuan, although exports fell by 3.7%, but China is still the world’s most important German sales market. ”

10 summers ago, VDMA set up a representative office in Beijing. Currently, there are over 600 VDMA member companies set up branches in China, located in Beijing and Shanghai representative office to provide information services to enter the Chinese market for these member companies. In fact, except for some of the effects of the global economic downturn on the market, and as more and more German companies in China launched a joint venture and cooperation, and some equipment has been implemented for the production of localized, so sales are no longer included in the import and export data data, which is also one of the reasons the German side exports decline.

German-Chinese trade is not a one-way street

Recalling 2004 VDMA newly established office in the Chinese, German bilateral trade volume in the mechanical equipment of approximately 70 billion yuan, and by 2013, this figure had reached 166 billion yuan. 2013, China’s exports of machinery and equipment to the German trade total 33 billion yuan. Germany in the EU is now China’s largest trading partner. First quarter of 2013, Chinese exports rose against Germany by 14%, while Germany’s exports to China fell by 3%. “German machinery exports to China trend is still no sign of rising. Nevertheless, we still export situation in 2014 remains optimistic about the second quarter, in the second half of this year and hopes to have a better performance, achieved in 2014 in Germany machinery and equipment exports to China-digit growth is expected. “said Dr. Festge.

Machinery and equipment exports only part of the Sino-German bilateral cooperation. In the past 10 years, China is already the world’s best investment among the best in the country. German machinery manufacturing industry in China’s direct investment in 2004 from 5.7 billion yuan in 2012 rose to 40 billion yuan. “China immediately after the United States, Germany’s most important business in the overseas market, the stage can be sure that the next few years, the number of branches of our member companies in China will exceed the number in the United States.” Festge doctor said.

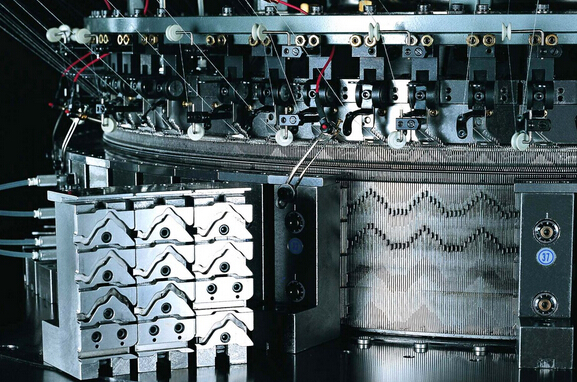

Textile industry advocates “blue energy efficiency.”

China International Textile Machinery Exhibition ITMA Asia Exhibition held in Shanghai in June this year, the German Embassy Consul General in Shanghai WofgangR? Hua hr attended the German textile machinery industry association VDMA to the Chinese textile industry launched the “blue energy efficiency” Technical News conference, who personally introduced to the industry of Germany advanced technology and energy management applications. In the textile industry, the application of blue energy efficiency technologies in Germany has covered the whole process of textile production and supply chain. Through higher energy efficiency, more reliable production technology to help textile manufacturers to save costs, win more profitable returns. It is estimated that if energy efficiency technology in the blue cotton knit T-shirt production, integrated energy conservation will reach 28%; If for advertising banner manufacturing, will be achieved energy savings of 26%; using German technology to produce functional T-shirt, make comprehensive energy consumption is reduced by about 1/3. In the process of this transformation and upgrading of China’s textile industry advocates, the German textile machinery manufacturing advanced energy-saving and environmental protection technology, has attracted attention across multiple industries wool, chemical fiber, industrial areas, etc., and for the production and processing of high-end products to provide high-quality and low-power technical support. At present, the scale of the German textile machinery exports industry was 30 billion euros, of which China is Germany’s textile industry’s most important export market.

Tremendous opportunities for Chinese space

“If you want long-term development of enterprises in China need to be clear in the end products to hit the market strategy.” VDMA chief StephanieHeydolph of German companies in China made such recommendations. China’s machinery and equipment has huge potential demand. In the next 15 years, China’s population of 2/3 will be settled in the city, the acceleration of urbanization is bound to bring the upgrading of technical equipment. Garbage collection, wastewater treatment, urban water supply, food sanitation, urban transport and other issues are facing challenges. Machinery and equipment from Germany in many ways hydropower, wind energy, etc. have a proven solution. These technologies will continue over the next 10 years in a leading position.

Reporters at the press conference Q & A session, one of the most challenging problems, Dr. Festge asked is: “Now China’s macroeconomic slowdown, some foreign disinvestment phenomenon emerged in China, the German machinery industry whether the same ? considerations, “Dr. Festge replied:” Although the past year, the German machinery industry in Europe experienced an economic downturn in the Spanish market; market in South America, Brazil experienced a more severe inflation, but German companies are only moderately reduced scale, did not intend to withdraw because we promised would not leave easily, especially for the Chinese market. “