1. structural analysis of circular knitting machine Transmission

To solve this problem, we must first understand the current transmission methods and principles of several commonly used on the market, analyze their strengths and weaknesses.

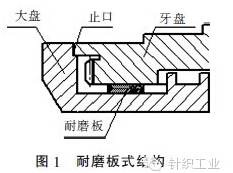

1.1 wear-plate structure

Wear-plate structure, also known as the slider type, shown in Figure 1.

This configuration process is simple, low cost, its disadvantage is that a large load. On the one hand, sliding friction and wear piece crankset between will have a greater load; the other hand, due to the small gap with the broader market ended the mouth and tooth plate, when the machine is running friction between the tape and dental plate generates heat , resulting in expansion of the outer tooth plate, resulting in increased load, if the gap is enlarged, will affect the radial positioning accuracy. Further, the friction between the parts subject to wear of parts, especially at the outlet of the wear stop, directly reduces the radial positioning accuracy, it is extremely difficult to repair. Although the wear plate and ended the mouth using a range of new wear-resistant materials such as Teflon, especially, greatly reducing the wear and tear, but the load is unavoidable, especially during cold start-up. In addition, because crankset rely on the market since the weight of the performance of its poor resistance to axial impact.

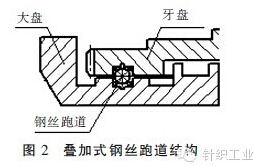

1.2 Modular structure of steel track

This structure is similar to the structure of the wear plate, and the steel balls instead of just using the wear plate, the sliding friction to rolling friction variation, shown in Figure 2.

And wear plate structure, as this structure is also relying crankset on the market since the weight, so the poor performance of its anti-axial impact. There is a saying that: Due to the structure of the load is too light, high-speed operation when the machine will produce buoyancy crankset rise, while another theory is that this phenomenon does not exist, when the rotating cranks level, will produce buoyancy However, this depends on the size and direction of the buoyancy of the shape and speed crankset to crankset now the situation knitting machine, but also unable to produce so crankset overcome its own weight increase buoyancy. Further, this structure requires high machining accuracy, the manufacturing cost is high.

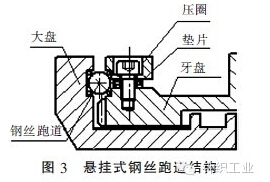

1.3 Hanging wire runway structure

This structure is different from the first two shown in Figure 3.

This structure not only run a small load, but a strong performance anti-axial and radial shocks. After the machine long run, due to the wear of the wire and the ball leaving the running accuracy crankset reduced (ie, in the case of poor stability issues raised), then you can resume running accuracy Withdrawal gasket dental plate. By this structure requires high manufacturing precision machining techniques to ensure its manufacturing cost is also high.

2. circular knitting machine FAQ

Understanding the structure of these three kinds of work we can easily find that operating performance steel structure to be far better than the runway wear-plate structure.

In actual operation, the part of the track structure using steel machine running accuracy indeed exist decline (ie, poor stability) situation. The reason is due to higher steel track structure requires precision machining and assembly technology, the machine can not be reached in many parts manufacturing or assembling precision due, not structural problems. Currently on the market, most of the Japanese production of circular machines use more runway stacking steel structures, European countries (such as Germany) production of circular machines use more runway hanging wire structure, reduced accuracy problems were not there. Fundamentally speaking, the use of structural steel circular runway appeared precision machine design drop phenomenon is not part of the problem, but the processing, manufacturing, material selection and other aspects of the problem.

Choose what kind of structure, and machine manufacturers design, manufacturing ability. From the practical effects look, wear plate structure compared to the original, stacking steel track structure design is reasonable, and hanging wire track structure is most reasonable, but also three kinds of structures in the most advanced.

Thus, to ensure the stability of the machine precision, the need to understand the quality of each brand and market reaction at the time of purchase the machine, do not blindly freeloaders or believe in advertising, marketing. In addition, with energy prices rising, the cost of electricity in weaving the proportion is growing, low-power performance advantages of steel structures on the runway more obvious. Therefore, the use of steel circular knitting runway transmission structure is the inevitable trend of future development.

Post: Transmission Characteristics of Double Circular Knitting Machine, and FAQ

This article was written by Jeawin of The Zhenlihua, a leading china circular knitting machine manufacturer, supplier & exporter. The company was committed to the researching, developing, producing and selling of circular knitting machines. Contact us today to receive the E-Catalogue. Reproductions of this article are encouraged but must include a link back to http://www.circularknittingmachinesale.com/